-

Bruno NascimentoThank you for your continued help and support in providing us with high-quality and affordable products.

Bruno NascimentoThank you for your continued help and support in providing us with high-quality and affordable products. -

Ehsan SalmariPrompt reply and professional attitude make our cooperation smoother!

Ehsan SalmariPrompt reply and professional attitude make our cooperation smoother!

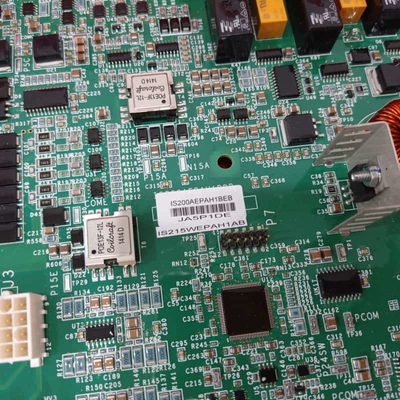

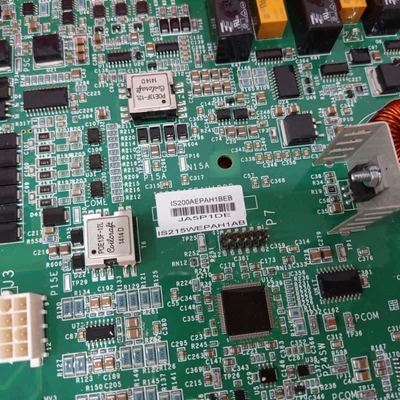

GE IS215WEPAH1AB Wind Pitch Axis Control Module Mark VI

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | GE IS215WEPAH1AB Canbus Wind Pitch Axis Control Module | Product ID | IS215WEPAH1AB |

|---|---|---|---|

| Product Net Weight | 2kg | Series | Mark VI |

| Product Net Width | 100mm | Product Net Height | 200mm |

| Product Net Depth/Length | 330mm | Warranty | 1 Year |

| Highlight | GE wind turbine pitch control module,turbine pitch axis controller,GE IS215WEPAH1AB control module |

||

| Attribute | Value |

|---|---|

| Name | GE IS215WEPAH1AB Canbus Wind Pitch Axis Control Module |

| Product ID | IS215WEPAH1AB |

| Product Net Weight | 2kg |

| Series | Mark VI |

| Product Net Width | 100mm |

| Product Net Height | 200mm |

| Product Net Depth/Length | 330mm |

| Warranty | 1 Year |

The GE IS215WEPAH1AB is an RTD Card in the Speedtronic Mark VI turbine control system, designed for precise temperature monitoring in gas, steam, and wind turbine operations. As part of the 330mm series, it specializes in processing signals from Resistance Temperature Detectors, critical for tracking thermal conditions in turbine components like exhaust sections and bearings.

Integral to the Mark VI architecture, this card converts RTD resistance changes into actionable temperature data, enabling real-time system adjustments and safety protocols. It features robust industrial design with conformal coating to resist harsh environments, ensuring reliability in high-temperature or dusty settings. Equipped with diagnostic LEDs and secure connectors, it simplifies installation and troubleshooting, supporting seamless integration into turbine control racks.

- RTD Signal Processing: Converts RTD inputs into accurate temperature data for critical turbine components, enabling thermal condition monitoring.

- Mark VI Integration: Seamlessly fits Speedtronic systems, supporting gas, steam, and wind turbine control architectures.

- Industrial Durability: Conformal coating protects against moisture, dust, and temperature extremes, ensuring long-term reliability.

- Diagnostic Support: Front-panel LEDs indicate operational status, facilitating quick fault detection and maintenance.

- 330mm Series Compatibility: Designed for 330mm turbine control racks, optimizing space and connectivity in industrial setups.

- Safety Focus: Provides vital thermal data to trigger protective actions, enhancing turbine operational safety and efficiency.