-

Bruno NascimentoThank you for your continued help and support in providing us with high-quality and affordable products.

Bruno NascimentoThank you for your continued help and support in providing us with high-quality and affordable products. -

Ehsan SalmariPrompt reply and professional attitude make our cooperation smoother!

Ehsan SalmariPrompt reply and professional attitude make our cooperation smoother!

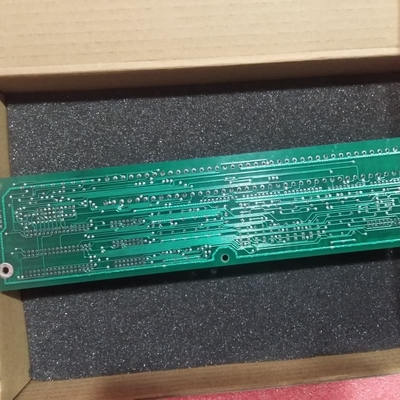

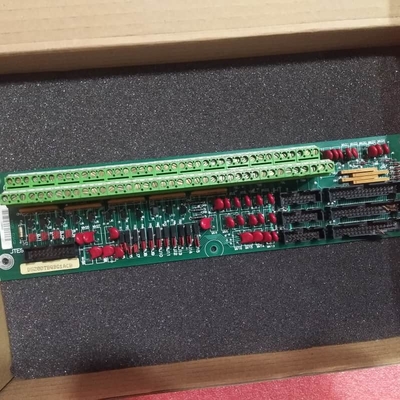

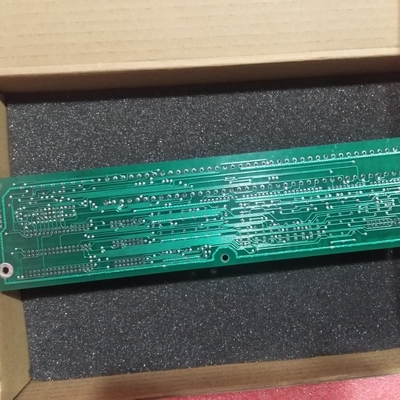

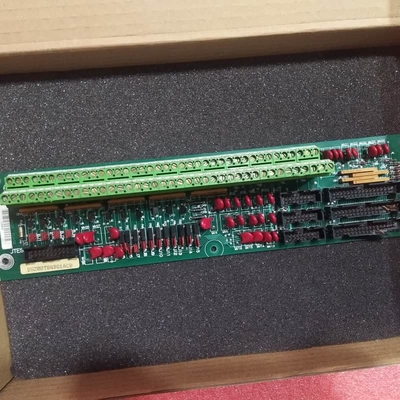

GE DS200TBQBG1ACB Input Termination Module 330mm x 200mm

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | GE DS200TBQBG1ACB Input Termination Module | Product ID | DS200TBQBG1ACB |

|---|---|---|---|

| Series | Mark V | Function | Discrete Output Pack |

| Product Net Depth/Length | 330mm | Product Net Height | 200mm |

| Product Net Width | 100mm | Product Net Weight | 2kg |

| Warranty | 1year | ||

| Highlight | GE DS200TBQBG1ACB termination module,GE turbine control input module,330mm x 200mm termination board |

||

GE DS200TBQBG1ACB Input Termination Module

Product Details:

The GE DS200TBQBG1ACB is an Input/Analog Termination Module designed exclusively for GE’s Mark V Turbine Control System—a high-demand legacy series used to manage wind, steam, and gas turbine automated drives, and one of the final GE Mark lines to integrate patented Speedtronic control technology.

Its core functionality revolves around centralized signal management: it receives and transmits critical inputs including voltage signals for electrical parameter monitoring, vibration signals for mechanical integrity checks, pulse rate signals for event frequency tracking, and compressor stall detection signals for safety pre-warning. It integrates seamlessly with Mark V’s TCQA and TCQC boards: in the R2 core, it connects to TCQA/TCQC boards in the R1 core for cross-core data coordination; in the R3 core, it links to local TCQA/TCQC boards for localized signal processing.

Hardware-wise, the module features two terminal blocks with 77 terminals each for copper signal wire connections, plus 15 Berg-type jumpers and a mix of connectors. The jumpers serve specialized roles: BJ1-BJ4 fan out pressure transducer signals, BJ5-BJ7 install burden resistors for pressure transducers, and BJ8-BJ15 configure analog inputs. For replacement, terminal identification simplifies wire reconnection—users label wires with terminal IDs, release them from the old board, and secure bare copper ends to matching terminals on the new board via screws.

Key Features:

Dual-Core Positioning & Cross-Core Integration: Located in R2/R3 cores with tailored connections to TCQA/TCQC boards——cross-core for R2, local for R3, enabling both coordinated cross-system monitoring and localized signal processing.

Multi-Signal Handling for Turbine Safety & Performance: Manages a diverse set of critical inputs to monitor turbine health, prevent mechanical failures, and ensure operational safety.

Specialized Jumper Configuration: 15 Berg-type jumpers with dedicated roles pressure transducer signal fan-out, burden resistor installation, analog input setup offer targeted customization for turbine-specific sensing needs.

High-Density, Labeled Terminal Blocks: Two 77-terminal blocks with numerical terminal IDs simplify wire tracking during installation/replacement, reducing reconnection errors.

Scalable Connector Design: Reserved JGS/T/JHS/T connectors provide flexibility for future system expansions, adapting to evolving turbine control requirements without full board replacement.

![]()

![]()

| DS200DTBBG1ABB | DS200TCCAF1BDF |

| DS200SDCIG2AFB | IS200ISBBG1AAB |

| DS200SDCIG2AHB | IS200CABPG1BAA |

| DS200BDAAG1AAA | IS200DSFCG1AEB |

| DS200SIOBH1ABA | IS200DRLYH1BBB |