-

Bruno NascimentoThank you for your continued help and support in providing us with high-quality and affordable products.

Bruno NascimentoThank you for your continued help and support in providing us with high-quality and affordable products. -

Ehsan SalmariPrompt reply and professional attitude make our cooperation smoother!

Ehsan SalmariPrompt reply and professional attitude make our cooperation smoother!

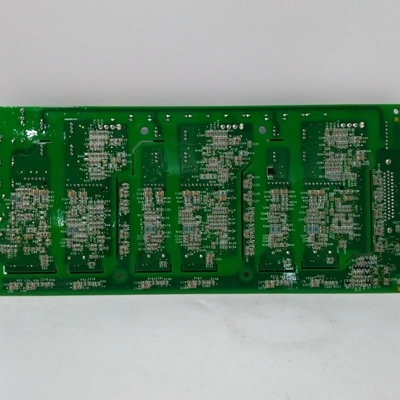

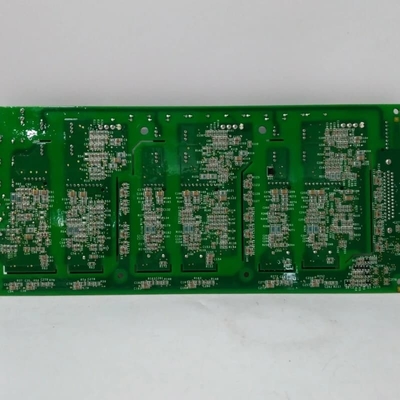

GE IS210AEBIH1BED AE Bridge Interface Card 330mm x 200mm

| Name | GE IS210AEBIH1BED AE Bridge Interface Card | Product ID | IS210AEBIH1BED |

|---|---|---|---|

| Series | Mark VI | Function | Input Terminal Board |

| Product Net Depth/Length | 330mm | Product Net Height | 200mm |

| Product Net Width | 100mm | Product Net Weight | 2kg |

| Warranty | 1year | ||

| Highlight | GE AE Bridge Interface Card,GE Turbine Control Interface Card,IS210AEBIH1BED Interface Card 330mm |

||

| Attribute | Value |

|---|---|

| Name | GE IS210AEBIH1BED AE Bridge Interface Card |

| Product ID | IS210AEBIH1BED |

| Series | Mark VI |

| Function | Input Terminal Board |

| Product Net Depth/Length | 330mm |

| Product Net Height | 200mm |

| Product Net Width | 100mm |

| Product Net Weight | 2kg |

| Warranty | 1 year |

The GE IS210AEBIH1BED is an AE Bridge Interface Card, a specialized component for GE’s industrial control systems—typically aligned with the Mark Series used in turbine, power generation, and heavy industrial setups. Its core role is to act as a communication bridge, facilitating seamless data transfer between disparate system components like controllers, I/O modules, terminal boards, that may use different protocols or signal types.

Engineered for industrial resilience, it likely operates within -30 to 65°C and features robust construction to withstand vibration, electrical noise, and dust common in turbine facilities. The “1BED” designation denotes specific functional revisions or component configurations, ensuring compatibility with Mark Series ecosystems.

Compact and designed for modular integration, it include dedicated connectors for input/output signals and diagnostic elements for real-time fault detection. By enabling reliable inter-component communication, it enhances the cohesion of control systems—critical for maintaining stable turbine operation, process regulation, and equipment safety in mission-critical industrial environments.

![]()