-

Bruno NascimentoThank you for your continued help and support in providing us with high-quality and affordable products.

Bruno NascimentoThank you for your continued help and support in providing us with high-quality and affordable products. -

Ehsan SalmariPrompt reply and professional attitude make our cooperation smoother!

Ehsan SalmariPrompt reply and professional attitude make our cooperation smoother!

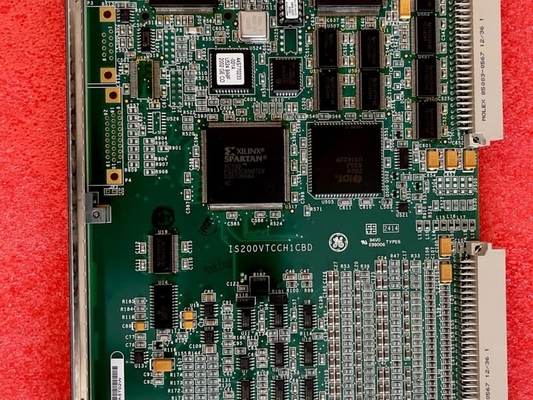

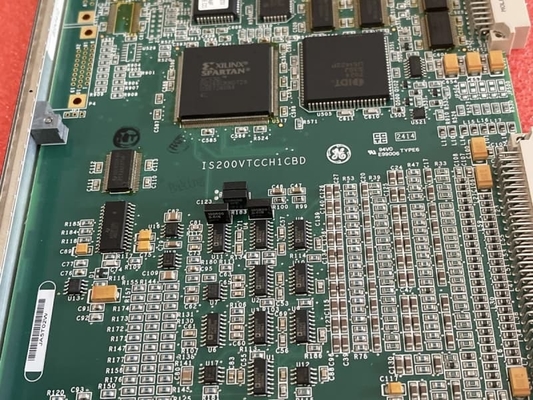

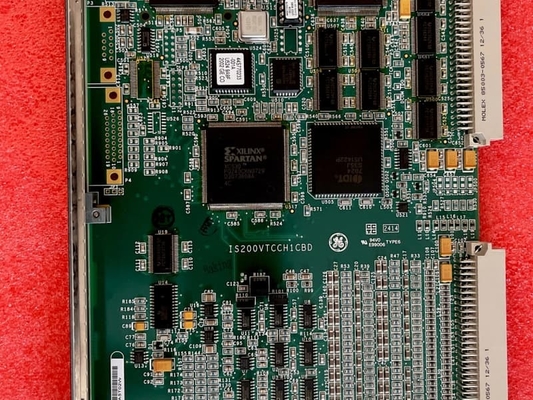

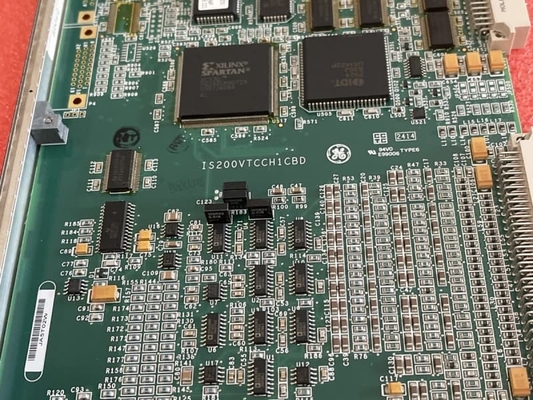

GE IS200VTCCH1C Mark VI Turbine Control PCB

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | GE IS200VTCCH1C Printed Circuit Board | Product ID | IS200VTCCH1C |

|---|---|---|---|

| Series | Mark VI | Function | Discrete Output Pack |

| Product Net Depth/Length | 330mm | Product Net Height | 200mm |

| Product Net Width | 100mm | Product Net Weight | 2kg |

| Warranty | 1year | ||

| Highlight | GE Mark VI turbine control PCB,turbine control PCB with warranty,GE IS200VTCCH1C control board |

||

| Attribute | Value |

|---|---|

| Name | GE IS200VTCCH1C Printed Circuit Board |

| Product ID | IS200VTCCH1C |

| Series | Mark VI |

| Function | Discrete Output pack |

| Dimensions (L×W×H) | 330mm × 100mm × 200mm |

| Weight | 2kg |

| Warranty | 1 year |

The GE IS200VTCCH1C is a Printed Circuit Board integral to GE's Mark VI Speedtronic system, designed for turbine control applications. This critical component facilitates control and monitoring functions, handling discrete or analog signals to manage turbine operations including fuel flow, temperature, and pressure regulation.

Compatible with both simplex and TMR configurations, the board integrates with VME racks via standard connectors for seamless communication with other system components. Its robust hardware design includes integrated circuits, relays, and terminal connections, all optimized for industrial durability. Diagnostic LEDs on the front panel provide clear operational status indicators for efficient troubleshooting.

Engineered for harsh environments, the IS200VTCCH1C delivers reliable performance in gas, steam, and wind turbine applications, enhancing overall system stability and safety. Its design fully supports the advanced control capabilities of the Mark VI system, making it an essential component in turbine automation.